Wixii su'aalo ah oo ku saabsan alaabtayada ama liiska qiimaha, fadlan noogu dhaaf emailkaaga waxaanan kula xiriiri doonnaa 24 saacadood gudahood.

- + 86-523-86183388

- +86-18918158399

- kiet@chinakiet.com

Astaamaha Alaabta:

Beddel MT / T913-2002, waxaa loo habeyn karaa mid aan caadi ahayn sida uu qabo soo saaraha.

Qeexitaan kasta waxaa lagu siin karaa dhexroor yar oo biyo ah oo loo yaqaan 'hydraulic nuts' kaas oo loogu talagalay xoogga yar ee horay loo sii adkeeyay ee qaybta gudaha ee warshadda martida loo yahay iyo shuruudaha meelaynta cidhiidhiga ah.

Faahfaahin kasta waxaa loo qaybin karaa nooca habaynta giraanta hoose iyo nooca habaynta giraanta sare.

Taageerida isticmaalka bamka gacanta hydraulic cadaadiska aadka u sarreeya

Taageerida isticmaalka bamka hydraulic koronto ee cadaadiska sare

Taageerida isticmaalka bamka hydraulic pneumatic cadaadis ultra sarreeya

Sharaxaada Alaabta

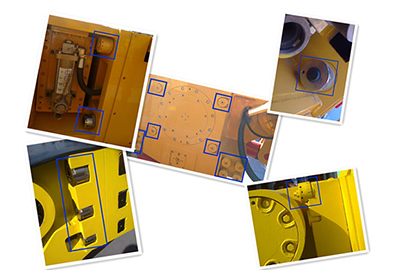

lowska Hydraulic oo ah nooc cusub oo ah qalabka hydraulic ee adag ee lagu xidho, ayaa si weyn loogu isticmaalay biraha, awooda, kiimikaad batroolka, mishiinada macdanta, mishiinka macdanta, mishiinka caajiska ah iyo mashiinada kale ee culus. Mashiinka macdanta dhuxusha waa xaqiijinta farsamada wax soo saarka dhuxusha iyo casriyeynta qalabka waaweyn ee waaweyn, qaybaha isku xirka isticmaalka qufulka hydraulic cadaadis ultra-sare ah. Sida kalsoonida sare leh, hawlgalka lagu kalsoonaan karo ee alaabta, nuts hydraulic ee macdanta cusub ee dhuxusha ayaa si ballaaran loo isticmaalay.

Xaaladaha kulanka dhulka hoostiisa aad bay u liidataa, oo leh qalab gacan si loo adkeeyo lawska caadiga ah, preload bolt inta badan ma aha ilaa shuruudaha preload, oo ay weheliso qaab-dhismeedka juqraafiga adag ee dhuxusha, dhuxusha dhuxusha inta badan la kulmo khaladaad, dhagaxyada, iyo si joogto ah u sita load saamaynta. Inta jeer ee gariirku aad buu u weyn yahay, deegaanka shaqadu aad ayuu u xun yahay, taasoo keentay in qaybaha ugu muhiimsan ee isku xirka xiiraya lowska ay dabciyaan, taasoo keentay in gudbinta xiirta iyo qaybaha kale ay waxyeelo gaarsiiyaan, si aad ah u saameeya wax soo saarka. Sidaa darteed, isku xirka boodhka ee u dhexeeya qaybaha ugu muhiimsan ee mashiinka dhuxusha waa inuu lahaadaa kalsooni sare.

Meelaha isku xirka ee qaybaha waaweyn, isticmaal nuts hydraulic inta u dhaxaysa qaybaha waaweyn iyo gunta hoose. waxay ogaan kartaa sanduuqa kontoroolka korantada ee mashiinka dhuxusha ee weyn, sanduuqa mashiinka korontada, sanduuqa korantada iyo sanduuqa dhexe ee isku xirka la isku halayn karo oo hubi in xiiriduhu si caadi ah shaqadu maaha mid dabacsan, si loo hubiyo badbaadada isticmaalka. Isla mar ahaantaana, isticmaalka boolal xoog sare si ay u fuliyaan isku xirka hoose, si loo xoojiyo saamaynta go'an. Tani waxay si wax ku ool ah u xallisaa dhibaatada dabacsanaanta sababtoo ah gariir xoog leh inta lagu jiro goynta caadiga ah ee dhuxusha iyo cilladaha, waxay yareysaa fashilka ay keento gariirka dhogorta, hagaajinta isku halaynta dhogorta, waxay si weyn u fududeysaa dayactirka maalinlaha ah ee dhogorta, waxay si weyn u fududaynaysaa dayactirka maalinlaha ah ee dhogorta, yaraynta xoogga shaqada ee shaqaalaha.

| Qaabka | Cabbirka boolka (mm) | Max. rarka hore (Kn) | Aagga Haydarooliga (mm2) | Dhexroorka ka baxsan (mm) | Dhererka lowska (mm) |

| KET-CLM-M30 | M16-M30 | 216.6 | 1571 | 74 | 66 |

| KET-CLM-M39 | M33-M39 | 349.4 | 2534 | 95 | 66 |

| KET-CLM-M52 | M42-M52 | 440.6 | 3195 | 108 | 74 |

| KET-CLM-M56 | M56 | 552.4 | 4006 | 118 | 78 |

| KET-CLM-M64 | M60-M64 | 617.3 | 4477 | 128 | 84 |

| KET-CLM-M68 | M68 | 777.1 | 5635 | 140 | 88 |

| KET-CLM-M80 | M72-M80 | 1040 | 7540 | 162 | 92 |

| KET-CLM-M90 | M80-M90 | 1462 | 10603 | 185 | 112 |

| KET-CLM-M100 | M90-M100 | 1625 | 11781 | 202 | 122 |

| KET-CLM-M105 | M100-M105 | 2079 | 15080 | 218 | 137 |

| KET-CLM-M115 | M110-M115 | 2209 | 16022 | 230 | 137 |

| KET-CLM-M130 | M120-M130 | 2339 | 16965kii | 240 | 143 |

| KET-CLM-M140 | M140 | 3108 | 22541 | 276 | 153 |

| KET-CLM-M150 | M150 | 3412 | 24740 | 300 | 162 |

|  |

| Magaca faylka | Qaabka | Luuqad | Soo deji faylka |

|---|